Polyurethane can be processed into various forms, including coatings, foams, thermoplastics, and molding materials. Its versatility extends to a wide range of medical applications, from flexible catheters to rigid implantable components.

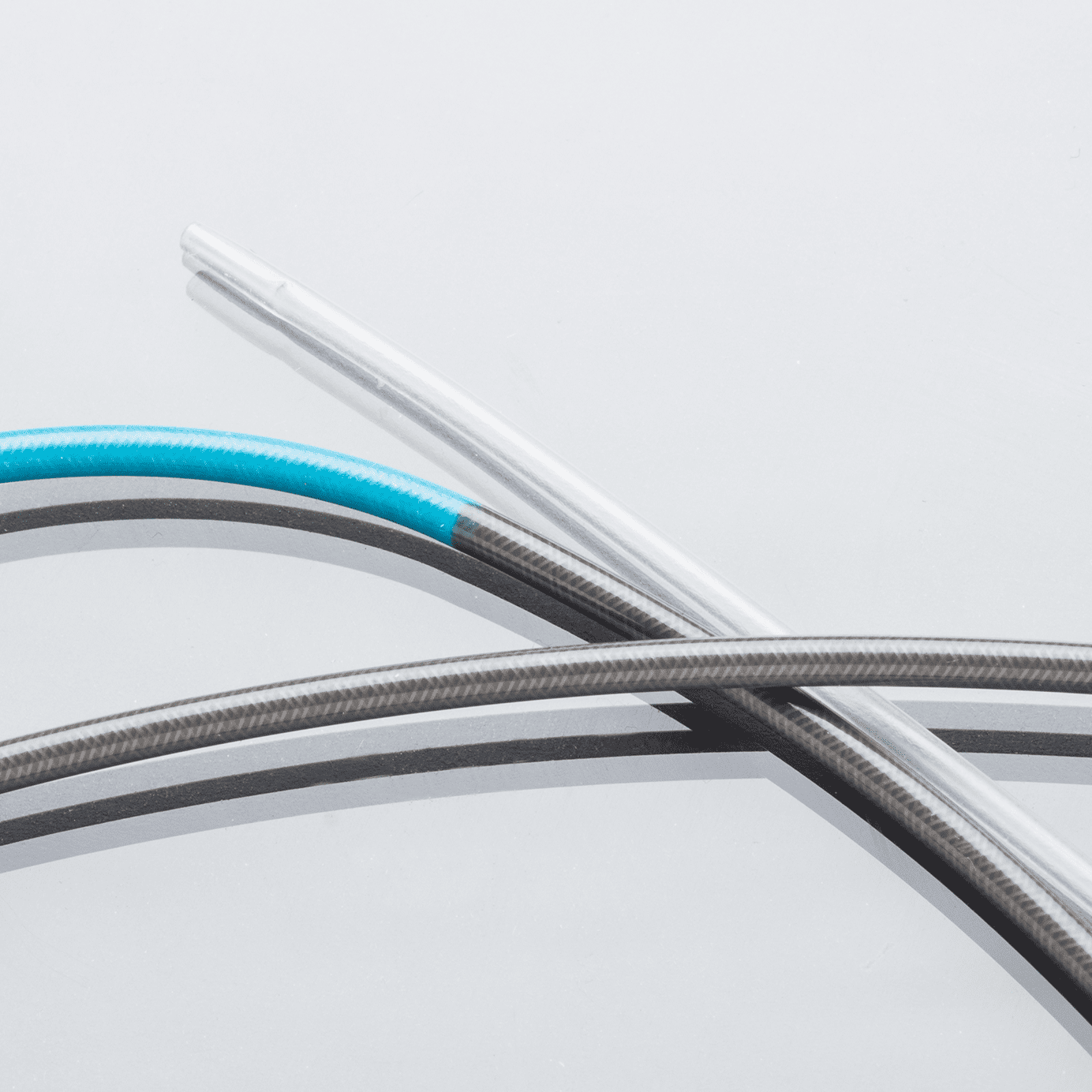

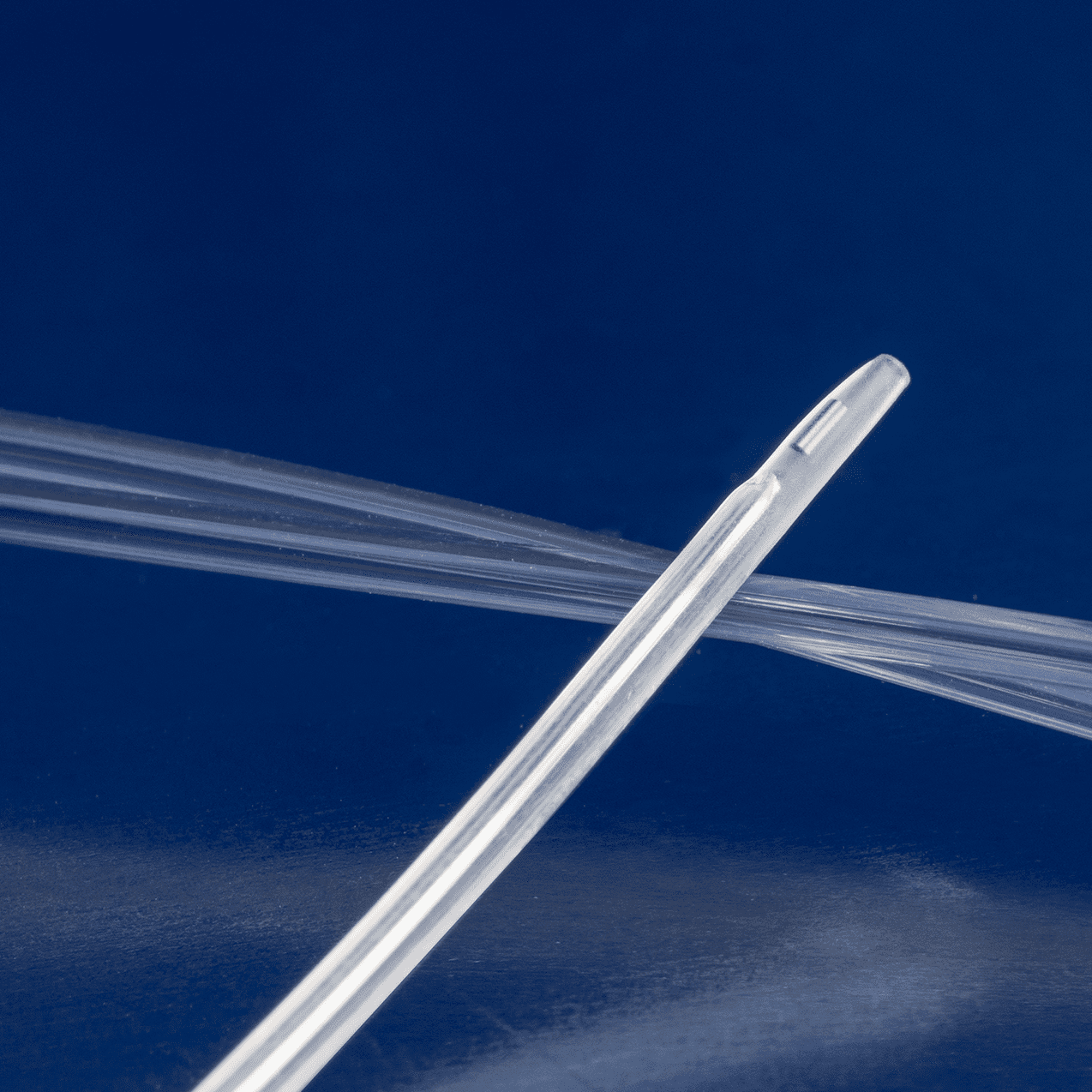

Catheters

Polyurethane's exceptional properties make it an ideal choice for various catheter applications:

- Flexibility and Biocompatibility:

- Smooth navigation through vascular pathways.

- Customizable Designs:

- Molded to various shapes and sizes for specific needs.

- Versatile Applications:

- Used in dip-cast or spray-coated embolic filters.

Implants

Polyurethane is widely used in the fabrication of implants due to its strength and compatibility with the human body. Applications include:

- Soft Tissue Implants: Polyurethane is used for its excellent elasticity and durability, making it suitable for soft tissue implants that need to mimic the mechanical properties of natural tissues.

- Shunts, Stents, and Grafts: Polyurethane’s flexibility and strength make it an ideal material for shunts, stents, and grafts, providing reliable support and reducing the risk of complications. Polyurethane is emerging as a new stent graft covering option as an alternative to polyester and ePTFE.

- Joint Implants: Polyurethane is increasingly used as a load bearing material in orthopedic applications ranging from synthetic cartilage in joint implants to spine implants.

Contact Us

Discover how our expertise in polyester can elevate your medical textile project. Contact us today to explore our capabilities.