Nitinol's versatility extends to various applications in the medical field, particularly in the manufacturing of catheters and implants.

Catheters

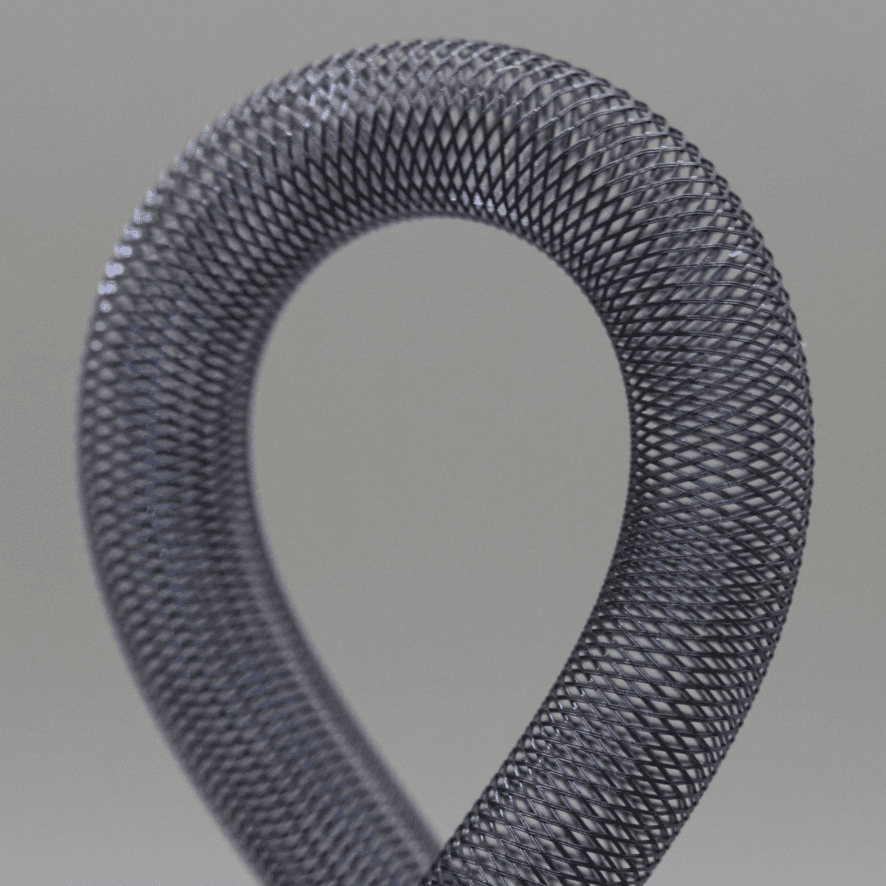

Nitinol's flexibility and kink resistance make it an ideal material for catheter construction. Braiding or coiling nitinol to reinforce catheter shafts enables a catheter to navigate through complex vascular pathways with ease, providing excellent support and stability. Nitinol is also crucial in the development of graspers, embolic filter frames, guidewires, and novel capture and release mechanisms.

Implants

Nitinol is widely used in the fabrication of stents and frames due to its superelasticity and biocompatibility. Applications include:

- Laser Cut Tubing for Stents and Frames: Nitinol's precision and flexibility make it perfect for creating stents and frames that need to expand and contract within the body while maintaining their shape and strength.

- Wire Formed Stents: Nitinol wire is used to create stents that can be compressed for insertion and then expand to support the vessel once in place, commonly referred to as Z-stents for stent grafts.

- Braided Stents: Braided Nitinol stents offer superior flexibility and conformability, adapting to the natural movements of the body and providing optimal support.

Contact Us

Discover how our expertise in Nitinol can elevate your medical device project. Contact us today to explore our capabilities.