Our Comprehensive Material Portfolio

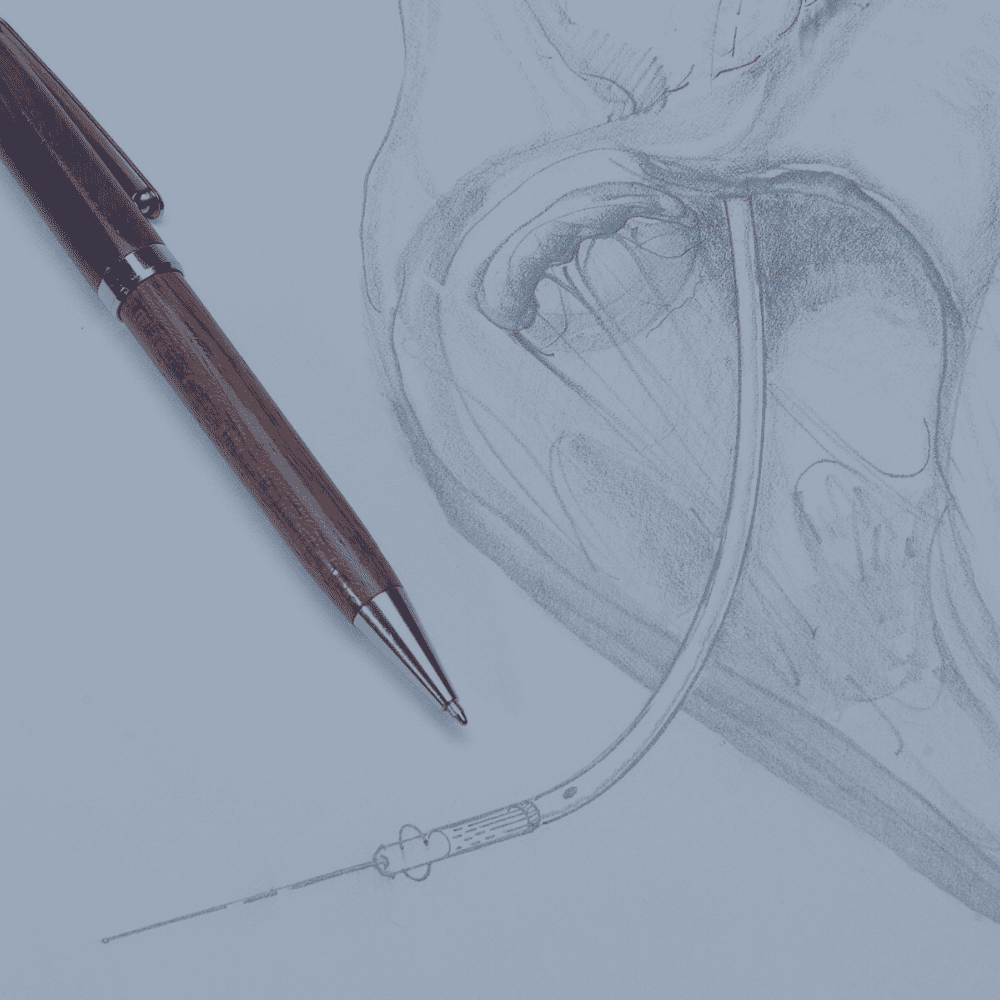

We work with a vast array of advanced materials to meet the diverse needs of our clients. Our broad material portfolio ensures that we can find the perfect solution for your unique medical device requirements.

ePTFE

Expanded polytetrafluoroethylene (ePTFE) is known for its biocompatibility and chemical resistance. Used in vascular grafts, stent coverings, and other implantable devices where long-term stability and compatibility are essential.

Nitinol

Nitinol’s superelasticity and shape memory make it ideal for catheters and implants. Its ability to return to its original shape after deformation ensures reliable performance in stents, frames, and other minimally invasive devices.

Bioabsorbable Polymers

Bioabsorbable polymers are designed to degrade safely within the body over time. They are used in temporary implants and drug delivery systems, offering the advantage of eliminating the need for surgical removal.

Polyester

Polyester's durability and flexibility make it a preferred material for biomedical textiles. It is used in applications ranging from surgical drapes to implantable meshes and stent grafts, providing strength and reliability.

Polyurethane

Polyurethane offers exceptional flexibility, biocompatibility, and durability. It is used in catheters, soft tissue implants, and joint implants, adapting to various shapes and providing long-term performance.

Silicone

Silicone’s biocompatibility, flexibility, and stability make it ideal for a wide range of medical devices. It is commonly used in catheters, wound dressings, and implantable components, providing reliable performance and patient comfort.

Key Considerations in Material Selection

When selecting materials for medical devices, several critical factors must be considered:

Our Expertise

Our team at Medical Murray understands that each medical device has unique requirements and challenges. We leverage our expertise to identify and utilize the best materials for your specific application. Whether you need flexibility, biocompatibility, strength, or a combination of these properties, we ensure that your device meets the highest standards of quality and performance.

Contact Us

Contact us today to learn how our expertise in material technologies can elevate your next project.