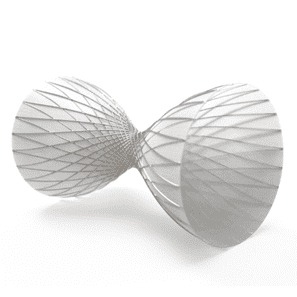

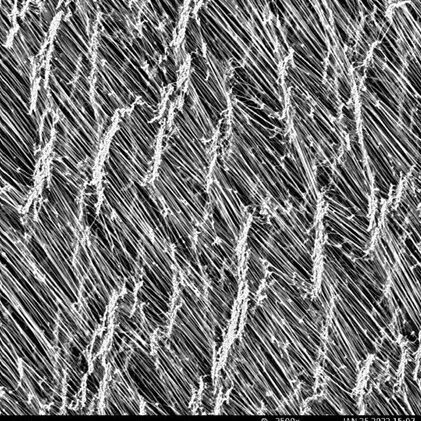

Medical Murray is your trusted leader of ePTFE processing for medical device applications. ePTFE, or expanded polytetrafluoroethylene, is made from the same polymer as Teflon but expanded to create a porous structure. ePTFE can be processed with structural orientation to be very thin while maintaining high strength, integrity, flexibility and controlled porosity. Medical Murray utilizes ePTFE for:

- Stent and frame coverings (e.g. stent grafts and heart implants)

- Medical textiles (e.g. patches, scaffolds and mesh)

- Vascular grafts and intestinal liners

Medical Murray can develop ePTFE specifications to be formed as extruded or electrospun membrane, flat sheets or tubing. Medical Murray can tailor the manufacturing processes when integrating ePTFE into your device to meet specific requirements for:

- Shape (we welcome unique and challenging profiles)

- Outer Diameter (2mm - 40mm)

- Thickness (20um minimum)

- Porosity

- Internodal Distance (10um - 100um)

- Density

- Flexibility

- Strength

Check out our article on medical device applications for ePTFE to learn more.