In the world of minimally invasive medicine, precision is everything. Whether it’s a heart procedure, a delicate neurovascular intervention, or placing a stent in a complicated artery, the ability to navigate the body with pinpoint accuracy is crucial.

Steerable and deflectable catheters are game-changing technologies that have drastically improved the way doctors perform these procedures. Let’s dive into how these catheters work, why they’re so vital, and how they continue to evolve to enhance patient outcomes.

What Are Steerable and Deflectable Catheters?

At their core, steerable and deflectable catheters are designed to give medical professionals superior control during minimally invasive procedures. These catheters allow for precise navigation through the body’s intricate network of veins, arteries, and other complex pathways, making procedures safer, faster, and more effective.

Steerable Catheters

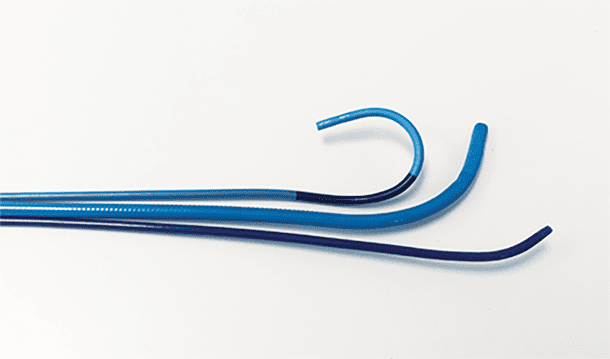

Think of these like the steering wheel of a car. They are designed for controlled navigation, allowing doctors to maneuver through the body with high precision. They’re widely used in procedures like electrophysiology (for mapping and treating heart rhythms), structural heart interventions, and even neurovascular treatments. A key feature of these catheters is their torque response – the ability to turn and rotate easily – making them highly effective in reaching even the most challenging locations.

Deflectable Catheters

These catheters take it a step further with flexible tips that can move independently from the catheter shaft. This added flexibility is essential for procedures that require precise angulation, such as ablation therapy or targeted implant delivery. Deflection is controlled by pull wires that run through the shaft, allowing for smooth tip articulation and ensuring the catheter can reach exactly where it’s needed.

Designing Catheters for Precision and Control

To truly enhance the performance of steerable and deflectable catheters, several design elements come into play:

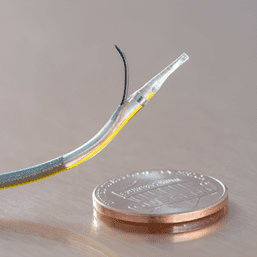

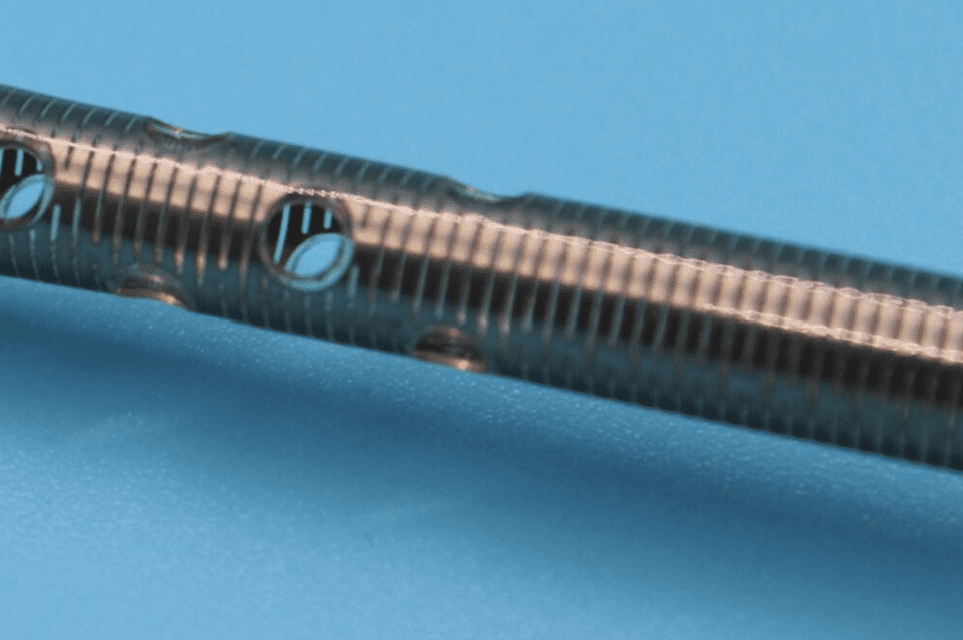

- Shaft Reinforcement: The catheter shaft needs to be flexible but also strong enough to handle the torque without kinking. Traditional materials like stainless steel and nitinol are often used to provide that perfect balance between flexibility and strength. Recently, laser-cut tubing has emerged as a cutting-edge technology, offering even greater control over the catheter’s flexibility and torque transmission.

- Pull Wire Mechanism: For deflectable catheters, the pull wires are key. They are typically made from high-strength materials like stainless steel or nitinol. Nitinol, in particular, offers superelastic properties, which means the catheter can maintain its shape and strength, even after repeated use. This is especially important in ensuring the longevity of the catheter and the success of the procedure.

- Ergonomic Handles: The handle of a catheter is where doctors have the most control, and modern catheter handles are designed for maximum precision. From rotary dials to trigger-based actuators, these handles allow the doctor to achieve smooth deflection and tip articulation, ensuring the catheter moves exactly as needed.

Revolutionizing Minimally Invasive Medical Procedures

So, where are these advanced catheters making the most impact? Let’s take a look at some of the most prominent applications:

Electrophysiology Procedures

Steerable and deflectable catheters have become essential in the treatment of arrhythmias. In cardiac mapping and ablation procedures, precision is key to delivering the right treatment. Deflectable catheters allow doctors to better contact the heart tissue, improving the efficiency of treatments and reducing procedure time. This translates to faster recovery and better outcomes for patients.

Implant Delivery Systems

Whether it’s placing a stent graft, a heart valve, or a neurovascular device, steerable catheters are crucial in ensuring these implants are positioned accurately. These catheters need to be flexible enough to navigate the body’s tortuous pathways while being rigid enough to deploy the implant correctly. Laser-cut hypotubes and hybrid reinforcement structures are used to achieve that balance.

Robotic-Assisted Systems

The future of catheter-based interventions is increasingly robotic. Robotic-controlled concentric tubes, for example, allow for multi-directional movement without the need for pull wires. This opens up new possibilities for accessing difficult-to-reach areas. Other innovations, like magnetically guided catheters and AI-assisted navigation, are also enhancing the precision and ease with which these procedures are performed.

Manufacturing Excellence: Crafting the Perfect Steerable Catheter

Creating a high-performing steerable or deflectable catheter requires cutting-edge manufacturing processes to ensure that each device meets the highest standards of quality, safety, and performance. Here are some of the key elements in the manufacturing process:

- Material Selection: To meet the rigorous demands of medical procedures, catheters need to be made from materials that offer both strength and flexibility. Common choices include Pebax® for flexibility, PTFE for its low friction properties, and nitinol for reinforcement.

- Prototyping and Testing: Before these catheters hit the operating room, they go through extensive prototyping and testing. Rapid prototyping allows manufacturers to quickly make design improvements, while rigorous testing ensures that each catheter complies with regulatory standards, such as ISO 10555, ensuring reliability and safety.

- Precision Manufacturing: Manufacturing catheters with such intricate designs requires state-of-the-art facilities. Cleanrooms with ISO Class 7 standards and advanced fabrication techniques, such as laser processing and precision molding, ensure that each catheter is built to the highest stan

Looking Toward the Future

The world of steerable and deflectable catheters is constantly evolving, with innovations in materials, design, and technology opening up new possibilities every day. From robotic-assisted systems to AI-guided procedures, the future of catheter technology holds incredible promise for improving patient care and outcomes.

As the medical field continues to embrace these advanced catheters, we can expect procedures to become even more precise, minimally invasive, and effective. The progress made in this field not only helps doctors deliver better care but also leads to quicker recovery times and improved quality of life for patients.

At the forefront of this innovation, Medical Murray is pushing the boundaries of catheter technology, designing solutions for some of the most challenging and complex medical applications. With each new advancement, steerable and deflectable catheters are making the future of medicine brighter and more precise than ever before.

Do you need help designing and manufacturing an advanced catheter? Contact us today to get started on your medical device manufacturing project!