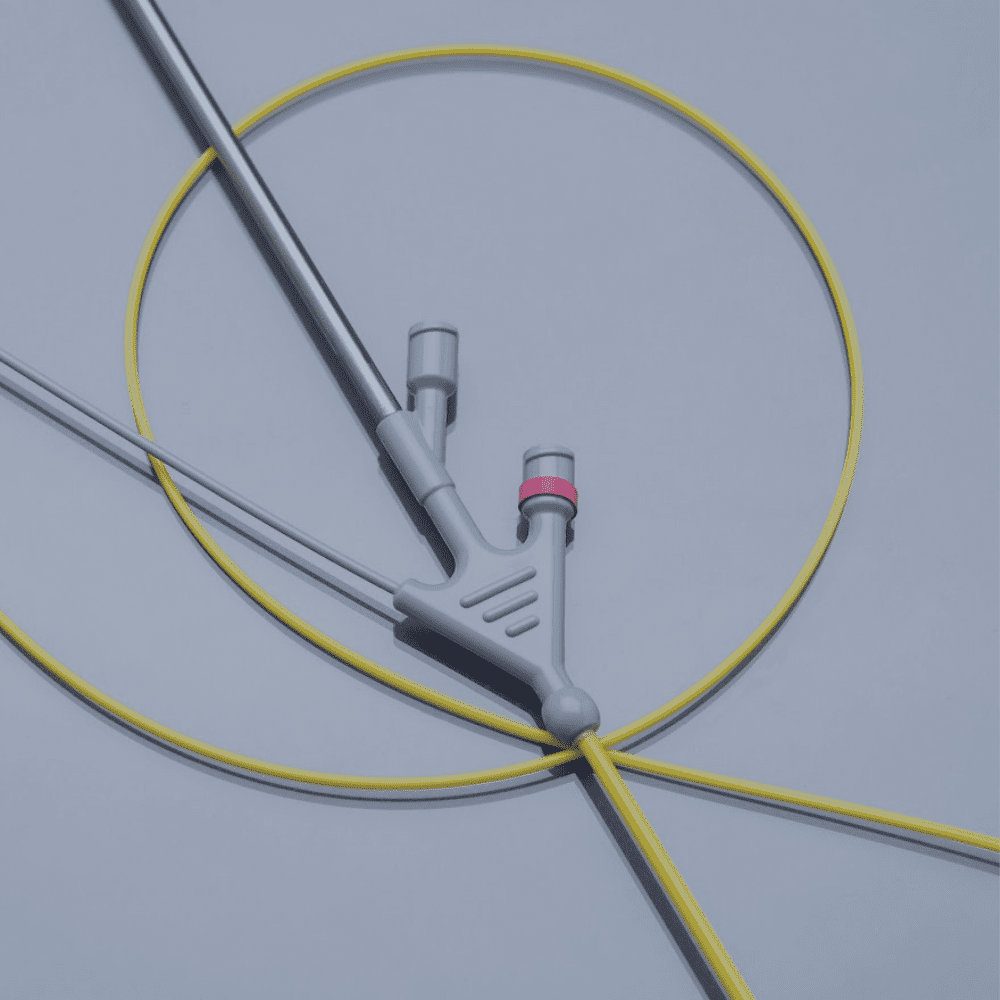

Made with Precision

Medical Murray's complete range of medical device manufacturing capabilities, custom equipment, and highly skilled operators allow us to produce complex, intricate devices to your specifications. All processes, including molding, are setup to run in our ISO Class 7 Cleanrooms.

We offer a full range of medical device production services from bulk, non-sterile components and subassemblies to packaged and sterile finished devices. We work with low- and high-volume orders, scaling to suit your production needs as they grow.

Our Manufacturing Process

Below are optional services when moving from prototyping to medical device manufacturing at Medical Murray:

- Assign Cross-Functional Transfer Team

- Review Processes and Design for Manufacturability (DFM)

- Prepare Process Flow Chart

- Identify Risks and Plan Validations

- Approve Vendors

- Plan Tooling and Fixtures