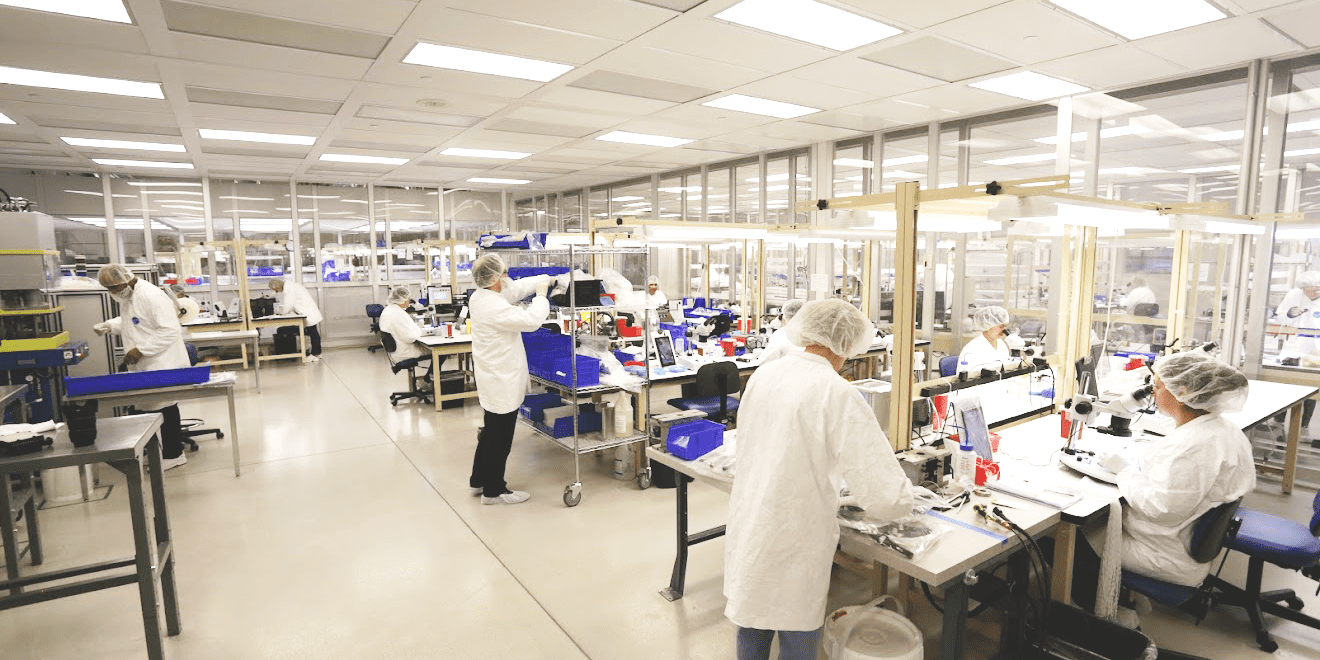

At Medical Murray, our medical device design engineers become an extension of your team. We deliver creative solutions for implants and catheters based on extensive device innovation experiences across a variety of markets. Our solutions consider three aspects: design features, material selection, and manufacturing methods.

Design for Manufacturing

We design medical products that meet performance requirements while staying aligned with your business goals by integrating design for manufacturing principles early in the development process. Medical Murray provides scalable prototype plans, Design for Manufacturing (DFM), and Design for Assembly (DFA) guidance that meets design specifications while staying within budget.

Medical Murray can also help you manufacture your product once the medical device design is ready to build. Learn more here.

Material Selection

Selecting the best materials can be as critical as the design features themselves. Medical Murray has extensive education and experience in selecting the optimal materials for single-use and implantable medical device designs. Our engineers are always experimenting with new and innovative materials to use in our development and prototyping processes.

Our materials experience allows us to consider these factors within the selection process

- Physical requirements

- Biocompatibility

- Chemical characteristics

- Processing methods & limitations

- Sterilization effects

- Shelf-life stability

Our Material Expertise

Medical Murray has extensive experience selecting the best materials for use in disposable and implantable devices and their delivery systems. Some of the materials we have worked with include:

Pebax

Pellathane

Tecoflex

Tecothane

Carbothane

Medalist MD-500

Grilamed

Polyimide

Silicone Rubber

Shafts

Pebax

Pellathane

Tecoflex

Tecothane

Carbothane

Medalist MD-500

Grilamed

Polyimide

Silicone Rubber

Handle & Luers

Polycarbonate

ABS

Polycarbonate-ABS

Nylon

Polypropylene

PETG

Liners

PTFE

FEP

Polyethylene

Hydrophilic Coatings

Implants

Silicone Rubber

Tecothane

Carbothane

ePTFE

Polysulfone

PEEK

Nitinol

316 Stainless Steel

Cobalt-Chromium

Reinforcement

316 Stainless Steel

Nitinol

PEEK

Aramid

Radiopacity

Gold

Platinum-Iridium (Pt-Ir)

Tungsten

Barium Sulfate

Balloons

Polyurethane

Pebax

Nylon

PET

Silicone

Versaflex TPE

Specialty

Silver Chloride

PMMA

TPX

Epoxy

Hydrogel

Foams

Nanoparticles