Blog

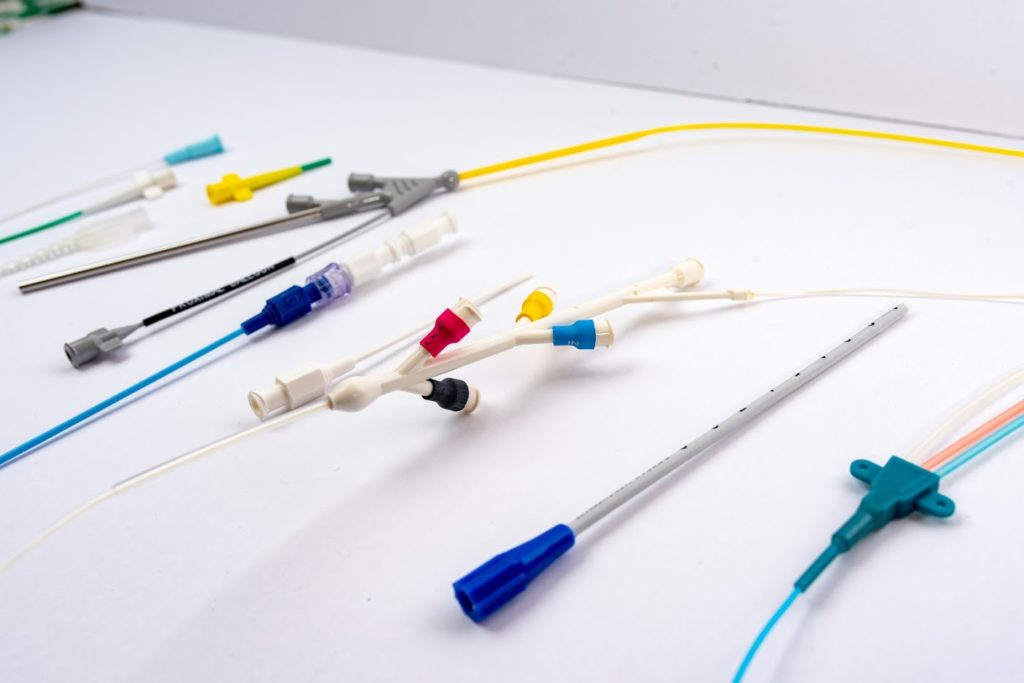

What It Takes to Develop and Manufacture Complex Catheters

Complex catheters are more than just flexible tubes. They are highly engineered tools designed to navigate the body’s most delicate pathways, deliver therapy, capture images, or deploy life-saving implants. Each section, from the soft tip to the handle, has a critical job to do. Getting it right demands a precise combination of expertise, equipment, and…

Read MoreNitinol in Medical Devices: Revolutionizing Catheter and Implant Manufacturing

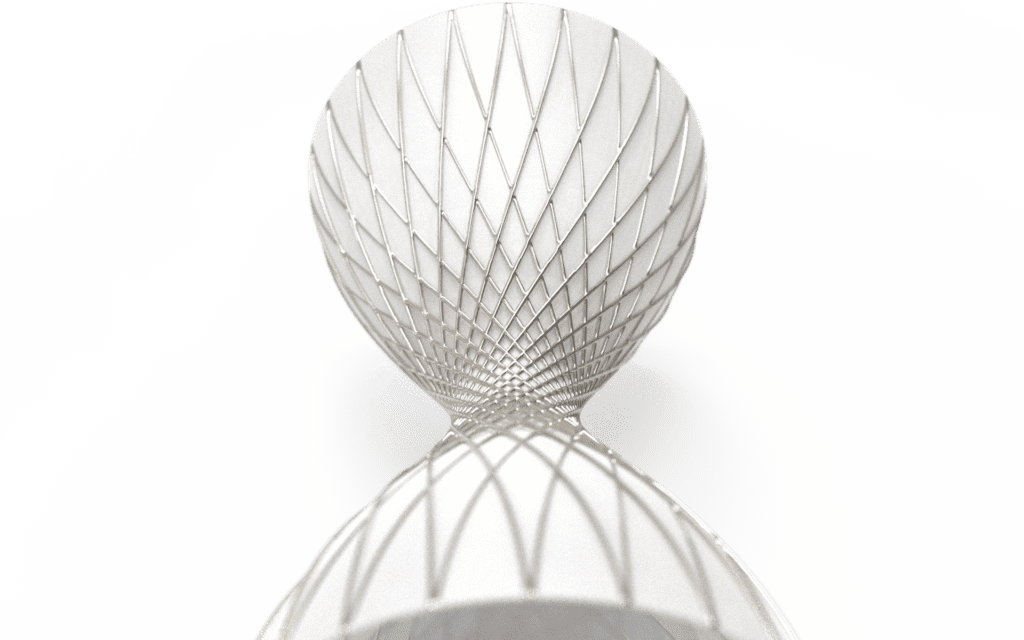

Ever wonder how medical device engineers transform a simple wire into a lifesaving, high-tech catheter or stent? The answer often lies in Nitinol, a nickel-titanium alloy that is loved for its shape memory and superelastic properties. In other words, bend it, flex it, even tie it in knots, and Nitinol will bounce back to its…

Read MoreMedical Murray’s Capabilities for Today’s Medical Device Trends

In our previous blog post, we highlighted key trends driving innovation in interventional medical devices. As these devices become more minimally invasive, digitally connected, and complex, Medical Murray strives to deliver practical, reliable solutions that help bring the next generation of devices to life. Here’s a look at how our team is equipped to tackle…

Read MoreThe Interventional Medical Device Landscape: Key Trends and the CDMO Market in 2025

The medical device industry is changing rapidly, with innovations in minimally invasive treatments, advanced biomaterials, and patient-focused care leading the way. In this evolving environment, the interventional device contract development and manufacturing organization (CDMO) market is playing an increasingly vital role. Below, we explore top device trends and discuss how CDMOs are helping original equipment…

Read MoreBraiding Techniques for Medical Devices

Braiding is a cornerstone of many interventional medical devices, including catheters, stents, guidewires, and biomedical structures. At Medical Murray, we use a variety of braiding methods to help our clients achieve optimal device performance. From basic braided tubing designs to advanced, customized braids with back-braided ends that minimize tissue trauma, braiding can enhance flexibility, kink…

Read MoreA Closer Look at Bioresorbable Polymer Implants

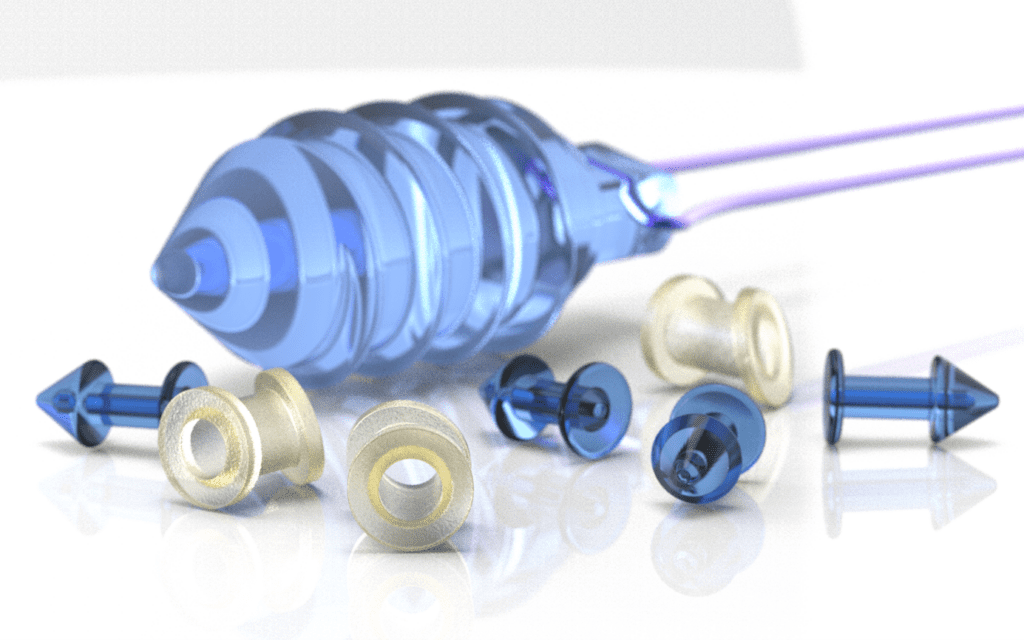

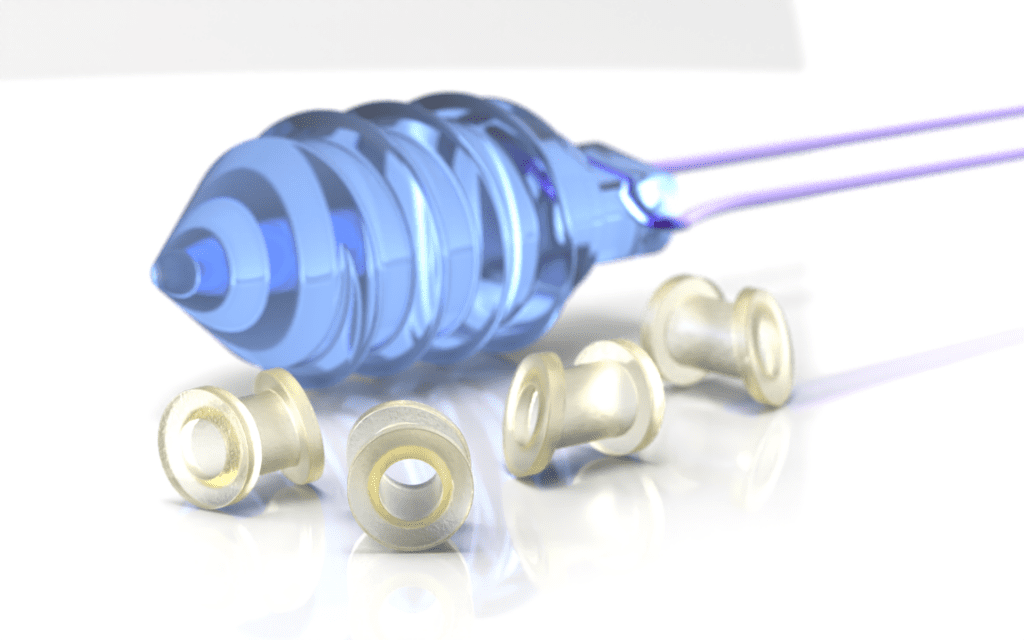

Why Bioresorbable Implants Matter Bioresorbable implants—made from polymers that gradually dissolve in the body—are transforming the medical device landscape. They serve their purpose during healing, then safely break down into byproducts the body can metabolize. By doing so, they eliminate the need for removal surgery and reduce the risk of complications often associated with permanent…

Read MoreMedical Device Manufacturing: Choosing the Right Path

When it comes to manufacturing complex medical devices like catheters and transcatheter implants, selecting the right pathway can make all the difference. Should you work with a CDMO to develop your device and transfer it into manufacturing? Or is your device already developed and ready for a manufacturing line transfer? Do you start with pilot…

Read MoreComplex Catheter Contract Manufacturing: Challenges, Examples, and Strategic Tips

The world of catheter innovation is advancing rapidly. With the growing complexity of medical procedures, the demand for catheters with advanced functionalities continues to rise. Unlike simple, well-established catheter designs, complex catheter manufacturing faces unique challenges in design, materials, and production. What Makes Complex Catheter Manufacturing Difficult? There are a few distinct challenges that make…

Read MoreComplex Catheter Contract Manufacturing: Challenges, Examples, and Strategic Tips

The world of catheter innovation is advancing rapidly. With the growing complexity of medical procedures, the demand for catheters with advanced functionalities continues to rise. Unlike simple, well-established catheter designs, complex catheter manufacturing faces unique challenges in design, materials, and production. What Makes Complex Catheter Manufacturing Difficult? Design Complexity Material and Manufacturing Challenges Regulatory Demands…

Read MoreWhy ePTFE is Revolutionizing Stent Grafts and Medical Devices

At Medical Murray, we’re passionate about driving innovation in medical device manufacturing. One material that continues to inspire us and transform the industry is expanded polytetrafluoroethylene (ePTFE). Known for its unmatched biocompatibility, durability, and flexibility, ePTFE is at the core of cutting-edge solutions for vascular, gastrointestinal, and surgical applications. Whether we’re crafting covered stent grafts…

Read More