A Specialized Catheter Manufacturer

For over twenty-five years, our dedicated engineering teams have worked collaboratively with our customers to deliver high-quality catheter prototypes and manufacturing solutions. Combining best-in-class catheter design, development, and manufacturing expertise, Medical Murray's purpose is to help healthcare providers offer a higher quality of care, giving patients greater quality of life.

Catheter Development and Testing

Catheters often require the integration of many different materials and components to achieve a balance between strength, flexibility, kink resistance, and torque response. Our team has designed hundreds of complex catheters with this balance in mind.

Our in-house research and development laboratories are equipped with stock materials and state-of-the-art capabilities to enable rapid prototyping efforts. We use Design for Manufacturing (DFM) and Design for Assembly (DFA) practices in early-stage development to greatly increase product viability and speed to market for our customers.

Medical Murray's ISO/IEC 17025:2017 accredited testing laboratories can accommodate catheter testing services performed according to customer approved protocols and to current ISO and ASTM standards. Along with the test reports, we can also help prepare your device's regulatory submission.

Catheter Manufacturing

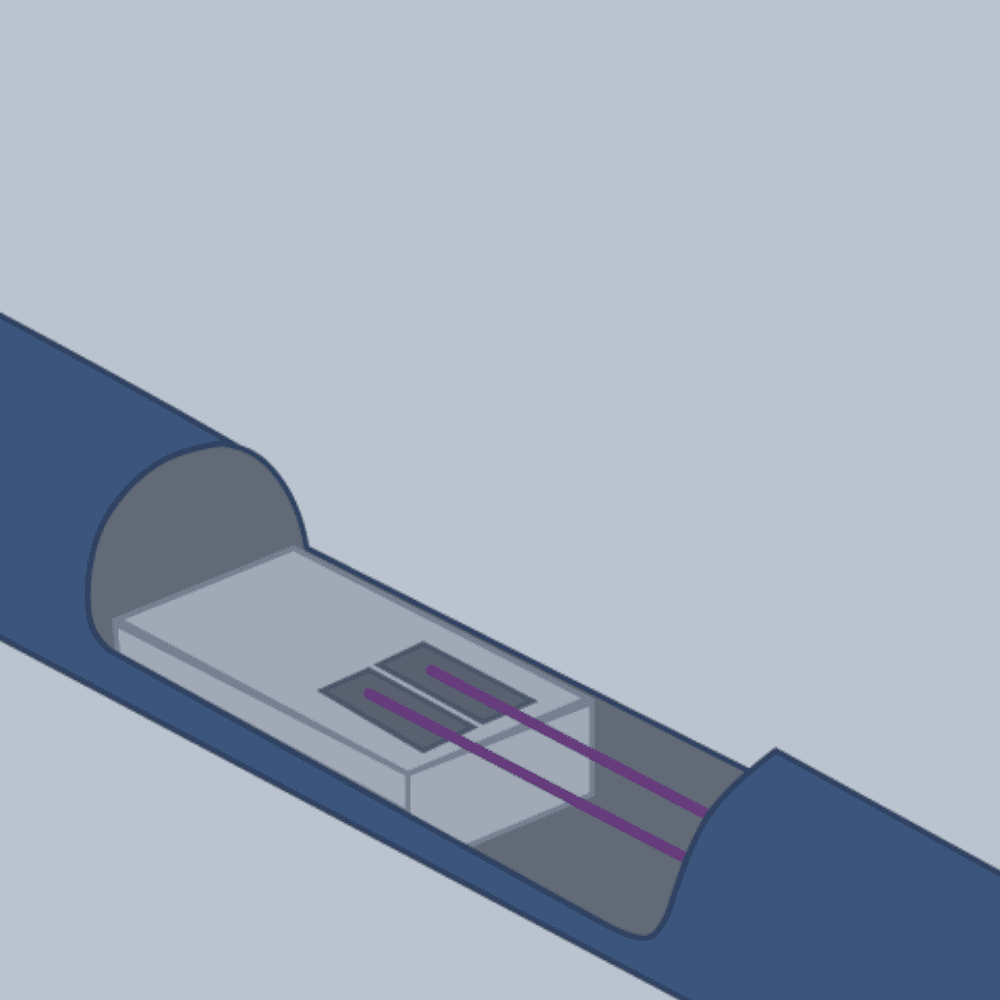

Pilot production of devices takes place in ISO Class 7 cleanrooms - available at all our facilities. The pilot production stage brings together engineering, process development, and quality systems to best refine processes and inspection requirements in preparation for full volume catheter manufacturing.

Medical Murray offers full-scale cleanroom manufacturing of your Class II and Class III catheter systems. Whether you need low volume or high volume, single components or finished device - we can accommodate your requirements on time and on budget. From intricate multi-lumen and multi-layer catheter assemblies including molded parts, to packaged and sterile products, we can produce your complex catheter for commercial launch and scale up as you grow.

Distal

Implant Loading

Balloons

Infusion

Tip Deflection

Radiopaque Markers

Sensors & Electrodes

Soft & Shaped Tips

Needles

Mid

Multi-Lumen

Low Friction Liners

Variable Stiffness

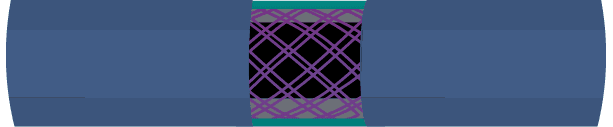

Torsional Reinforcements

Kink Resistance

Hydrophilic Coatings

Lead Wires

Braid / Coil Reinforcements

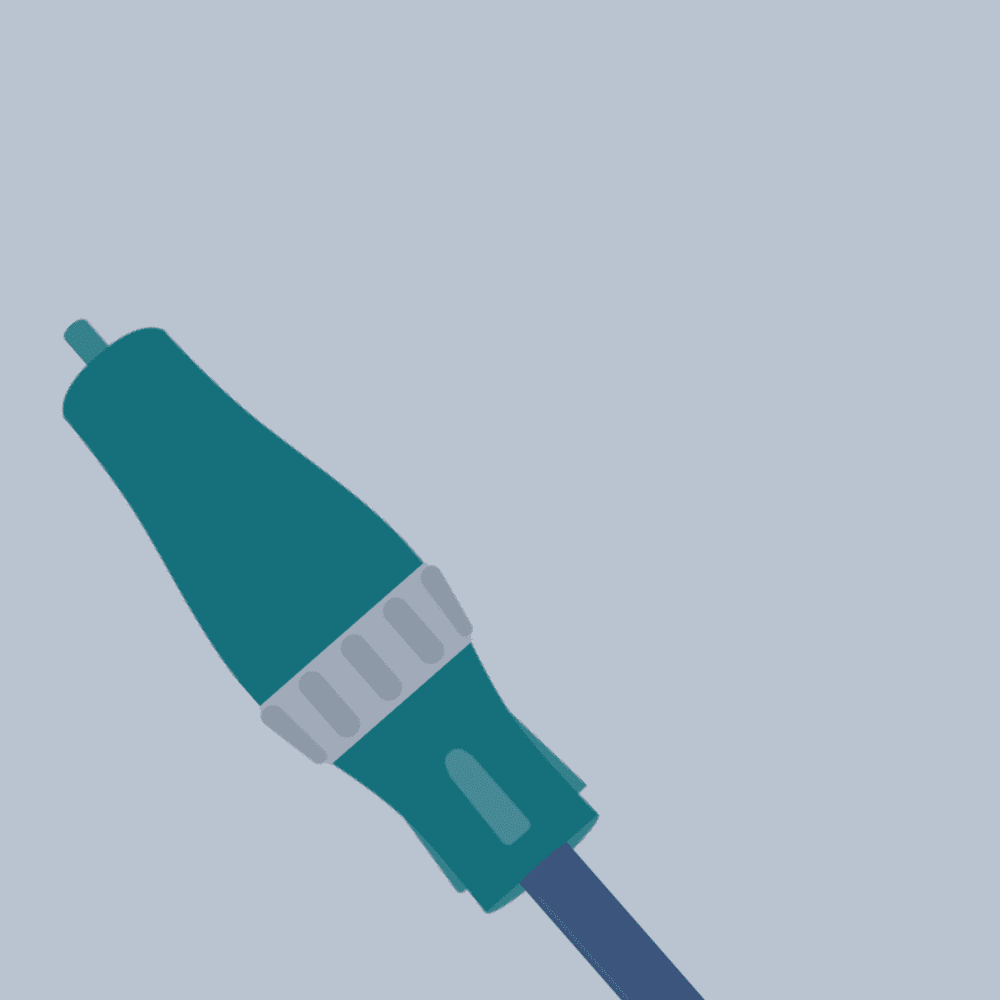

Proximal

Hemostatic Valves

Release Mechanisms

Steerable / Deflectable Handles

Side Ports / Luers

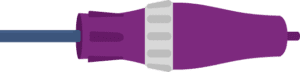

Over-Molded Hubs

Connectors