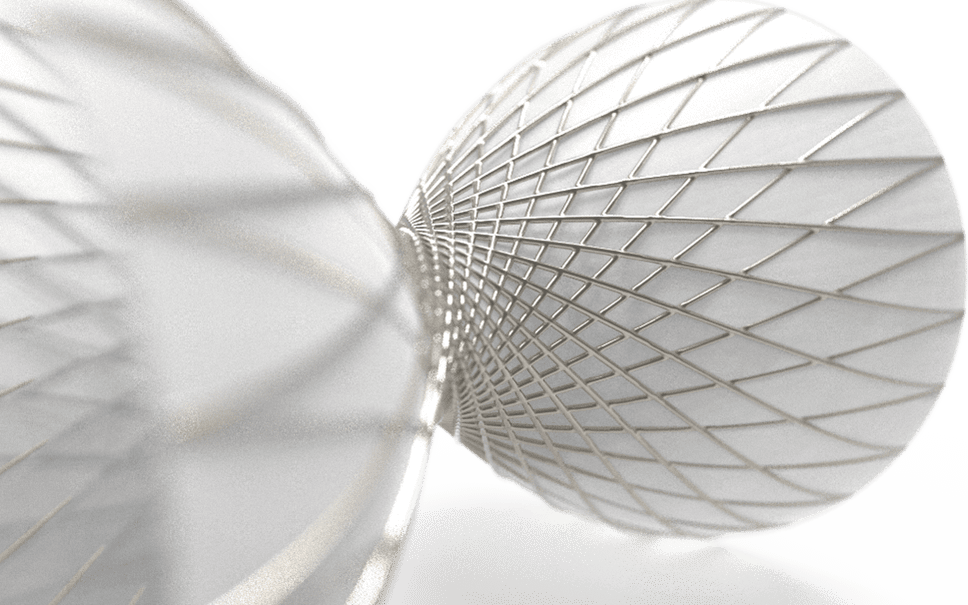

At Medical Murray, we are dedicated to advancing covered stent and frame technology for high-risk medical procedures. Our expertise in material selection and processing enables us to deliver customized, biocompatible solutions that meet the most demanding clinical needs. Using materials like ePTFE, polyester, polyurethanes, and silicones, we create devices optimized for durability, flexibility, and patient safety.

Why Covered Stents and Frames Are Essential

Covered stents and frames play a critical role in complex procedures, providing structural support and controlling blood flow. These devices help reduce the risk of complications and protect surrounding tissues, making them vital in cardiovascular, gastrointestinal, and other high-stress applications.

Advanced Covered Stent Materials for Optimal Performance

We offer a variety of materials for stent and frame coverings, each with unique benefits tailored to specific clinical needs.

ePTFE (expanded polytetrafluoroethylene)

Known for its ultra-thin profile, ePTFE is the thinnest of all our covering options, allowing devices to be loaded into smaller delivery systems. This reduces contraindications and expands the patient population eligible for these implants. At Medical Murray, we also use a proprietary sintering process to encapsulate ePTFE onto stents and frames, creating a seamless, durable covering. We further enhance ePTFE’s suture pull-out strength by customizing the material itself, ensuring it meets the demands of high-stress applications.

Polyester

Polyester coverings are strong and stable, making them ideal for applications where tissue integration is beneficial. We attach polyester by sewing—a method that promotes tissue ingrowth and anchors the implant securely. This approach is particularly useful in cardiovascular procedures that require stable device integration.

Polyurethanes and Silicones

These materials provide flexible, biocompatible coverings suitable for complex device shapes. Applied through dip coating or spray coating, polyurethanes and silicones offer smooth, durable finishes, making them ideal for devices requiring a compliant covering.

Benefits of Medical Murray’s Covered Stents and Frames

- Expanded Patient Population: With the ultra-thin ePTFE covering, we can create devices that fit into smaller delivery systems, minimizing contraindications and allowing a broader patient base to benefit from these devices.

- Long-Term Durability and Biocompatibility: Our materials are carefully chosen to minimize immune response and inflammation, promoting safer, long-term outcomes for patients.

- Reliability and Flexibility: Through advanced processing techniques like sintering, coating, and sewing, we ensure that each covering is both flexible and durable, able to adapt to complex anatomical structures.

How We Enhance Suture Pull-out Strength

For applications where secure attachment is critical, we go beyond traditional methods. By tailoring the ePTFE material itself, we increase its suture pull-out strength, making it more resilient and suited for high-stress environments. Our specialized sewing techniques also provide additional reinforcement when necessary, ensuring that each device performs reliably under challenging conditions.

Applications of Covered Stent Technology

Medical Murray’s covered stents and frames are used across various high-risk procedures, including:

- Vascular Grafts and Stents: ePTFE and polyester provide a stable, reliable covering for vascular applications, ensuring flexible support and ease of delivery.

- Heart Leaflets and Pericardial Patches: Customized material solutions enhance performance in cardiovascular applications.

- Gastrointestinal Sleeves: Flexible, biocompatible coverings minimize device size, making it easier to deliver implants to sensitive gastrointestinal areas.

Why Choose Medical Murray?

At Medical Murray, our expertise spans multiple materials and techniques, allowing us to tailor solutions to each unique clinical need. Our efficient production processes deliver high-quality devices while maintaining cost-effectiveness, maximizing the value we bring to every project.

Interested in learning more? Contact us today to discover how our innovative solutions in covered stents and frames can elevate your project. We’re here to help you bring reliable, high-performance devices to market, tailored for today’s most demanding medical applications.