When developing a Class III medical device, finding the right Contract Development and Manufacturing Organization (CDMO) is critical. These high-risk devices, such as implants and complex catheters, require precision, expertise, and full regulatory compliance. With so much at stake, it’s important to ask the right questions when selecting a partner to help you navigate medical device development and manufacturing.

Key Questions about Class III Medical Devices for your CDMO

At Medical Murray, we’ve helped many companies through this process. Here’s a straightforward guide to the key questions you should consider when evaluating a CDMO for your Class III medical device.

1. What’s their experience with Class III medical devices?

Class III devices demand a high level of expertise and precision. Your manufacturing partner should have a solid track record with similar products.

Ask your CDMO:

- How many Class III devices have you developed and manufactured?

- What types of Class III devices do you specialize in?

2. How do they handle regulatory compliance?

Class III devices must meet strict FDA and global regulations. Your CDMO needs to understand these requirements, even if they’re not the ones filing the submissions.

Ask your CDMO:

- How do you handle Design History Files (DHF) and Design Control compliance?

- Do you work with external regulatory experts for FDA and CE/MDR approvals?

3. Do they have the right manufacturing capabilities?

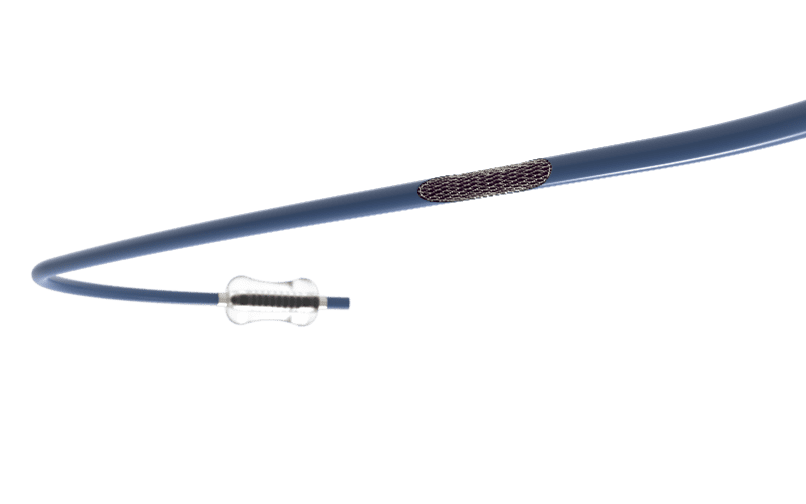

Manufacturing a Class III device requires specialized equipment and processes. Ask about the materials and technologies they’re experienced with, especially if your device has specific material requirements.

Ask your CDMO:

- What manufacturing technologies do you have for producing complex catheters and implants?

- Do you have experience with the specific materials we’ll be using, such as nitinol or bioresorbable polymers?

4. How do they manage their supply chain?

A strong supply chain is essential, especially for Class III devices where material quality and traceability are critical.

Ask your CDMO:

- How do you manage your supply chain to ensure material quality and traceability?

- Can you handle sourcing, or will we need to supply some materials?

5. What’s their approach to risk management and quality control?

Your CDMO should have a comprehensive risk management process in place, particularly for high-risk devices. Ensuring compliance with ISO 14971 and other standards is essential for a successful project.

Ask your CDMO:

- How do you integrate ISO 14971 risk management into your processes?

- What testing and validation do you perform to ensure compliance with FDA standards?

6. How do they manage projects and communication?

Transparent communication and project management are essential to keeping your project on track. Look for a CDMO that assigns a dedicated project manager and uses tools that keep you informed.

Ask your CDMO:

- Will we have a dedicated project manager?

- How will you keep us updated on project progress?

7. How do they protect intellectual property?

Your intellectual property is one of your company’s most valuable assets. Make sure your CDMO takes IP protection seriously.

Ask your CDMO:

- How do you protect our intellectual property?

- What confidentiality agreements are in place?

8. Are their pricing and timelines clear?

Cost overruns and delays are common risks in any medical device development project. Make sure your CDMO provides clear, upfront pricing and has a history of meeting deadlines.

Ask your CDMO:

- How do you structure your pricing?

- What’s your track record for meeting project deadlines?

9. What post-market support do they offer?

Even after your device is approved, the relationship with your CDMO should continue. Post-market support, including handling recalls and product updates, is essential for Class III devices.

Ask your CDMO:

- Do you offer post-market surveillance and support?

- How do you handle product recalls or modifications?

The Right Manufacturer for Class III Medical Devices

Choosing a CDMO for a Class III medical device isn’t a decision to take lightly. By asking these key questions, you can find a partner that understands the complexities of your project and has the experience to guide it through development, manufacturing, and beyond.

At Medical Murray, we’ve been helping companies develop and manufacture Class III devices for years. We’re here to answer your questions and provide the expertise you need to bring your product to life. Contact us today to learn how we can support your project.